Scorpion Stings

This morning is a Bahama best. A full moon hangs high in the northwest sky while a blazing sun wakes low in the east. The air is pinkurple. I hear nothing but Gerty’s clean hulls slipping through the rippling water. We’re heading toward a resting place—George Town, Great Exuma Island.

I hesitated for weeks to blog about our time in the boatyard, thinking nobody, including me, wanted to read about our blood, sweat, and tears. Then, I backtracked through our logbook and realized a record of our time there was worthy.

Ships log November 12, 2023

19:00 Arrived in St. Augustine, Florida. TWS 30 knots, anchorage turbulent. Mooring pick-up was a disaster. We broke the starboard forward stanchion. We tried anchoring in three different locations. Now we’re too tired and depressed (about the broken stanchion, spastic autopilot, and misbehaving watermaker) to go to shore.

Ships log November 13, 2023

17:00 Wavy! TWS 25+ knots. We see breaking waves in the channel as we exit the anchorage. Three reefs are in the main in preparation for a wild overnight sail.

Ships log November 14, 2023

02:30 TWS 3 knots. We’re motor sailing. One reef in the main, lumpy sea, rain. Ugh.

03:36 Squalls! Rain. 5-7′ waves. Ugh.

09:15 Arrive Scorpion Boatyard. Anxious, stressed. Gerty Outremer is hauled-out under our ownership for the first time.

Our to-do list was long, and our time (4 weeks) was short. We opted to stay in an affordable Airbnb, knowing that the luxury of a washing machine, fully operable kitchen, and easily accessible shower would make all the difference. Also, atypically for us, we outsourced some of the work. We hired the bottom paint team (Erick, Felix, and Rob) at Scorpion to do Gerty’s Copper Coat, and we added the detailing team (George and John) a few weeks in, realizing this was best for us, given our time, budget, and physical stamina. Our ultimate goal was to optimize the efficiency and safety of our boat, in turn reducing unnecessary maintenance work and unwanted surprises in the future. The following is a tally of what we accomplished (minus most of the setbacks.)

There’s a saying among sailors. “The highs are higher, and the lows are lower.” Early on, Michael whacked his head in the engine room when a stuck bolt on the rudder stock let loose, and seeing his blood, I was sure this would be our low point, but it wasn’t.

The fiberglassing-in-the-bilge days were awful, and when the glue on the old starboard emergency hatch refused to melt, I wasn’t sure if Michael or his smoking multi-tool would explode with frustration first. The nights I had to ice the pain from my aching hands were terrible. We complained to each other out of sheer exhaustion, and our patience grew thin.

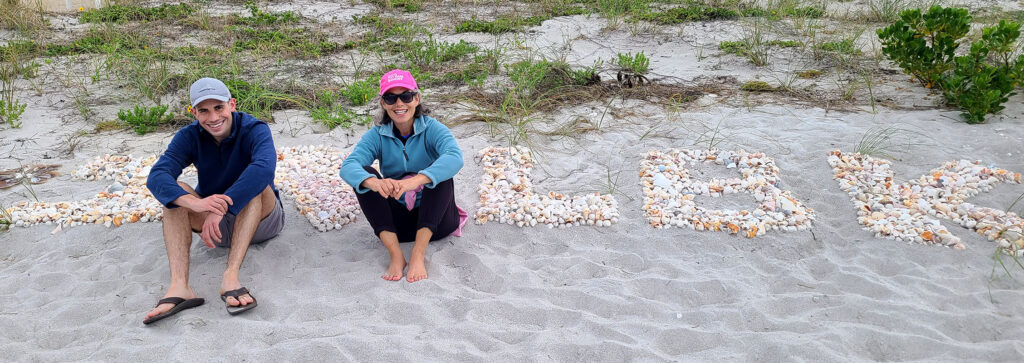

Thankfully, we got a much-needed pick-me-up at Thanksgiving. It’s incredible what family and turkey can do!

We returned to the boatyard with a firm end date in mind—December 12. In the mornings, Felix, Rob, John, and George would start work early, making us feel less alone. We hit a turning point when we finished the fiberglass work and another when we completed the port and starboard engine room projects. Ultimately, we got the job done. We splashed with six months’ worth of dry food goods, full fuel tanks, six expertly sewn (by Jill) fender covers to protect Gerty’s polished exterior, and a clean-bottom dinghy. I wouldn’t say we had hit our next high yet, but we were definitely on the way up!

Project’s Completed – Team Gerty (Jill & Michael)

- Eliminated unused thru-hulls and fittings below the waterline including:

- Port forward AC intake

- Strbd forward AC intake

- Salon AC intake

- Port aft old watermaker intake

- Port forward electro scan drain

- Strbd holding tank drain

- Installed new Goïot escape hatches port and starboard

- Adjusted and Tef-geled escape hatch handles

- Reinstalled VHF radio with fixed MMSI number (Recommend: Matt at service@sarts1.com)

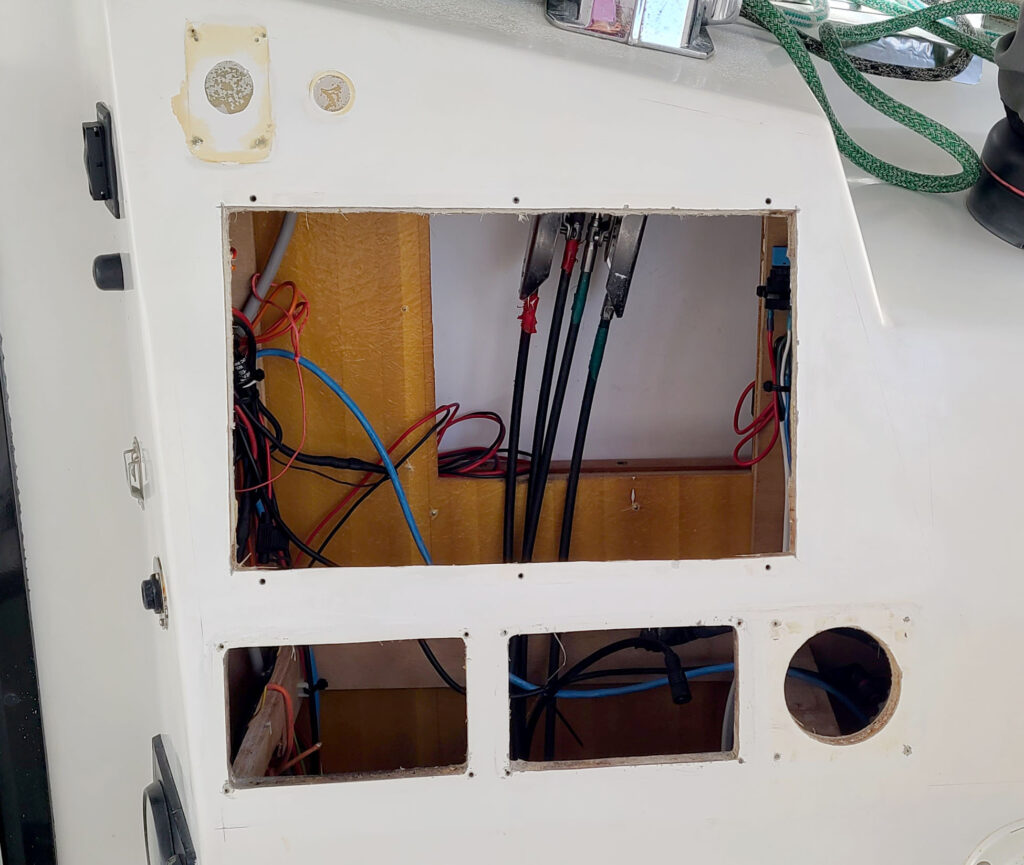

- Replaced the navigation station mounting panel with a vinyl-covered G10 plate laser cut to fit all new electronic displays.

- Installed new electronic instruments at the starboard helm station and patched holes (fiberglass, compound, gel coat) left where older instruments were removed.

- Serviced port top steering bearing

- Fiberglass, compound, gel coat holes at abandoned instruments port helm station.

- Repaired gel coat at swim platforms and under the deck

- Repaired nick starboard daggerboard trunk

- Serviced rudders (push bars, rudder stops, calibration, bearing/alignment, caulk, dropped for copper coat application)

- Removed, reset, and replaced damaged stanchions, bases, pad eyes, and u-bolt and base.

- Rewired and reinstalled shore power port

- Replaced refrigerator anodes

- Replaced small stern cleats with properly sized cleats

- Serviced propellers including Propspeed application

- Eliminated salon AC condensate drain

- Changed sail drive oil, port/starboard

- Installed new sail drives anodes

- Installed refurbished high-output alternators x 2. (Recommend Larry from Auto Electric Melbourne, FL c 631-664-5470, p 321-428-3573

- Installed new belts on alternators

- Replaced standard engine alternators with new OEM replacements

- Removed unnecessary engine room fittings port and starboard. Then, fiberglass repair, exterior fill, and gel coat finish of all engine room hull holes: old radar post mounting plate, 50 amp connection, 220 amp connection, passerelle connection, two small cleats, emergency tiller connection.

- Removed unnecessary grounding plates for old SSB radio and for the AC shore power, which has been redirected directly to the charger. AC on boat is now always through the inverter and not directly from the shore.

- Patched grounding anodes holes

- Changed engine oil, port/starboard

- Removed old and installed new port Racor Fuel Filters

- Corrosion X on Jefa drive unit and other engine components

- Installed starboard alternator protection devices port/starboard

- Sprayfoam port/starboard engine bulkheads where wires were removed.

- Sealed bulkhead behind starboard diesel tank where antennas were removed.

- Topped off Engine coolant

- Cleaned engine rooms

- Added decorative vinyl to the helm station

- Installed Triton2 and autopilot controller.

- Installed new helm/steering wheel

- Installed new depth transducer

- Antifouled thru hulls

- Upgraded main batteries’ fuse to class T

- Installed new fuel level sender

- Installed winch handle holders

Team Copper Coat (Felix & Rob)

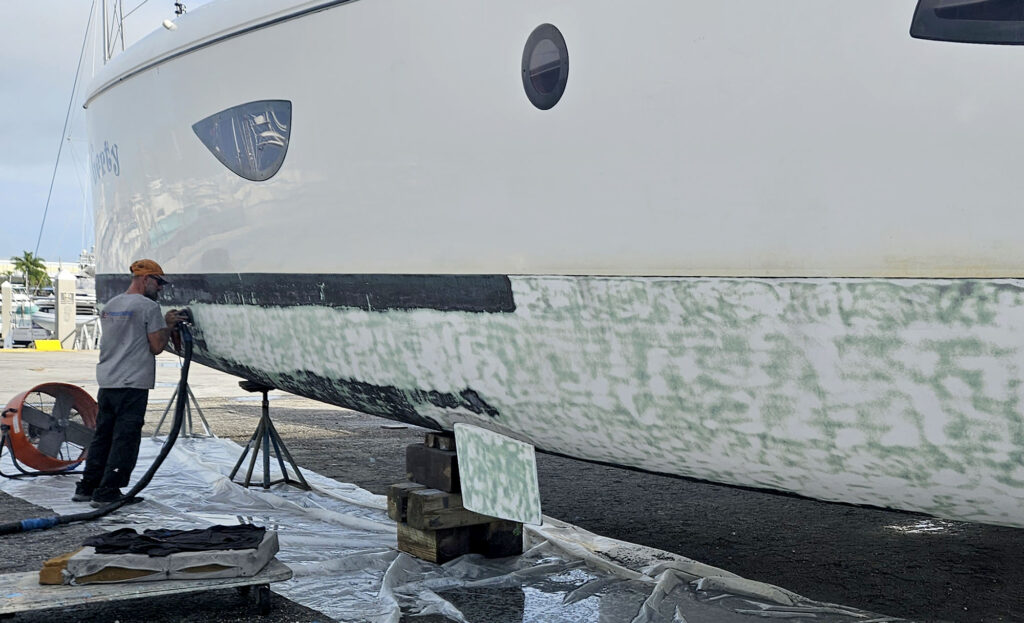

- Power washed hulls

- Chemical stripped hulls

- Power-washed hulls again

- Sanded hulls down to barrier coat, eliminating all antifouling

- Washed hulls

- Applied barrier coat to hulls

- Faired and sanded imperfections on the hulls

- Applied two more barrier coats

- Re-sanded hulls with medium grit sandpaper

- Washed hulls

- Applied five coats of Copper Coat to the starboard side on day one

- Applied five coats of Copper Coat to the port side on day two

- Let Copper Coat cure for three days and rest

- Sanded hulls to expose copper

- Lifted hulls and repositioned blocking. Then repeated the entire process on all the spots they missed!

Team Detail (George & John)

- Acid-washed the stains on hulls and topside toe rails

- Cleaned hulls and topside toe rail

- Compounded hulls and topside toe rail

- Wet sanded where necessary with 1200 grit sandpaper to polish

- Waxed hulls and topside toe rail

It seems like Gerty has been entirely rebuilt. I wish I could do the same for myself! the Thanksgiving pic is great, and definitely the best pic I’ve seen of Bonnie in years… beautiful.

Here’s to many more adventures and of course, smooth sailing!

Wow, what a list and long job well done! It looks gorgeous…just like you!! xx

Love the reports – good or bad. Keep ‘em coming!!

What a shock!

I thought Hemingway died decades ago, but no!

There he is with Janet and Bonnie from Sarasota 😱😱😱